150 kV Electron Beam Welding Machines

150 kV electron beam welding machines are extensively used in the aero engine, aerospace, and power generating industries. Typical parts include:

- Aerospace parts

- High-precision aero-engine parts

The higher accelerating voltage allows the beam to travel a longer distance – up to 1.5 m to the workpiece from the inside of the chamber. Other advantages include:

- Capable of welding larger workpieces

- Greater depth of penetration

- Greater depth of focus

- High positional accuracy of the weld is always maintained

- Less affected by external magnetic fields

XW Model

The XW model has a modular, flexible design to enhance production capabilities. The XW is ideal for welding medium and large sized components, and is also suitable for electrically conductive materials. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features

Tooling Options

Gallery

| Standard chamber sizes include

Other sizes are available upon request

|

1,400 x 1,000 x 1,250 mm

2,250 x 1,250 x 1,400 mm 1,800 x 1,800 x 1,800 mm 4,000 x 2,100x 3,000 mm |

| 150 kV beam power

|

Standard up to 6 kW (40 mA at 150 kV)

Optional up to 15 kW (100 mA at 15 0kV) and 30 kW (200 mA at 150 kV) |

| Gun vacuum | 10-5 mbar range |

| Chamber vacuum | 10-4 mbar range |

| Chamber pump down time (to 10-4 mbar) | Dependent on chamber volume, pump specification, and customer requirements |

- Air-conditioned electrical cabinet

- Beam deflection patterns

- Chamber viewing window

- Directly heated cathode

- eWon ethernet hub for remote diagnostics

- Filament alignment jig

- Function generator for application of welding patterns

- High-quality HDMI camera, with adjustable cross hairs and video capability

- Industrial PLC

- Mechanical and diffusion pumps for high-vacuum operation

- PC-based HMI, with recipe storage and data logging

- Separately pumped gun column (turbo-molecular)

- Automatic focus and alignment

- Automatic joint finder and imaging using back scattered electrons

- CNC control

- Dry vacuum pumps and cryo-coil

- High-speed data logger

- Horizontal gun mount

- Motorised gun-slide

- Motorised run-out platform

- Mylar film protector for CCTV

- Recirculating water chiller

- Special beam functions, including beam splitting

- Wire-feed

- XY table

- Chamber extensions

- Custom tooling

- Indexing carousel

- Internal rotary manipulator, tilt, and Z lift

- Tailstock

- XY table

XW Model

150 kV Gun Column

HMI with CNC Control

Five-axis manipulator (X, Y, R, T, Z)

CNC Controlled Wire-Feed

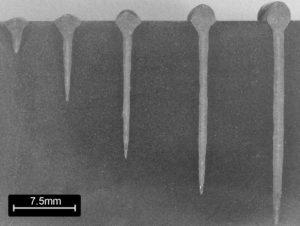

150kV Welds